What is the trace heating/ heat trace add on or heat sink?

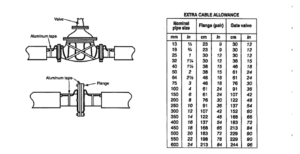

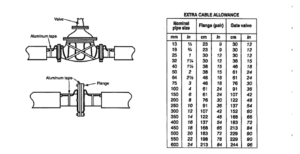

The extra heat trace cable allowance required for flanges valves and pipe shoes, See below table for more information:

The extra heat trace cable allowance required for flanges valves and pipe shoes, See below table for more information:

Heat Trace and insulation are required for exterior sprinkler pipes mainly in cold cities in Canada and USA. Sprinkler pipes heat trace and insulation must be designed carefully to protect pipes from freezing.

The Heat Trace circuit length/size will depend on the supplied voltage and amperage also it will depend on the cable wattage, its recommended to consult with Canstal engineering team to size the heat trace circuit.

All types of Heat Tracing cables must not touch themselves, and the only exception is the Self-regulating heating cable used for gutter and roof snow melting.